Understanding the nuances of your diesel engine’s exhaust system is crucial for proper maintenance and performance. The muffler and resonator play pivotal roles in managing noise levels and optimizing airflow, ensuring that your engine operates efficiently. Problems with these components can lead not only to increased noise but also to decreased engine performance and fuel efficiency.

One of the primary functions of the muffler is to reduce the sound produced by the exhaust gases exiting the engine. Over time, wear and tear, as well as exposure to extreme temperatures, can result in holes or cracks, causing unwanted noise and potentially harmful emissions. Similarly, the resonator, designed to improve sound quality and further refine the outgoing exhaust, can develop issues that may require immediate attention.

By identifying symptoms such as excessive noise, decreased engine performance, or unusual vibrations, you can pinpoint whether the muffler or resonator is the root cause of the problem. Regular inspection and maintenance of the exhaust system are essential to prevent minor issues from escalating into costly repairs. Understanding how to recognize these problems will empower you to take action before more serious damage occurs.

Diagnosing Unusual Exhaust Sounds from the Muffler

Unusual noise emanating from the muffler can indicate underlying issues that require immediate attention. When diagnosing these sounds, it is essential to differentiate between normal operational noise and irregular sounds that may suggest problems.

One common symptom is a loud rumbling or roaring noise, which may indicate a damaged muffler or exhaust leak. This sound typically occurs during acceleration and can be a sign that the internal baffles of the muffler are broken or that there is a hole in the exhaust system.

Another type of noise to listen for is a hissing or popping sound. This can be attributed to exhaust gases escaping through small openings or cracks in the muffler. Such leaks not only produce unwanted noise but also lead to decreased engine performance and increased emissions.

If you hear a sharp, metallic rattling noise, it might suggest that internal components of the muffler have become loose or degraded. This can cause a significant reduction in sound insulation and may require the replacement of the muffler.

Additionally, a high-pitched whine or whistle can indicate that there are blockages or restrictions within the exhaust system. Such issues often result from accumulated debris or foreign objects lodged in the muffler, necessitating a thorough inspection to restore optimal function.

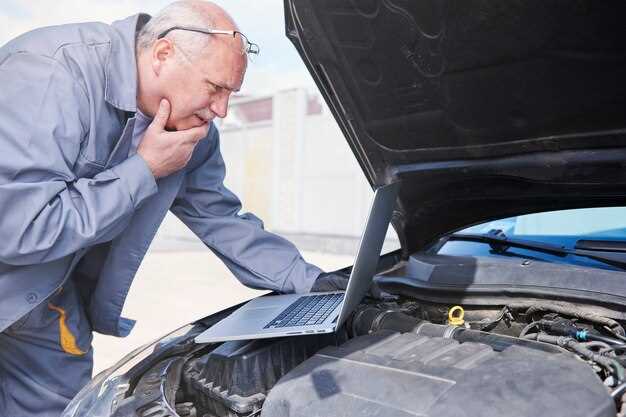

To properly diagnose these noises, it’s advisable to perform a visual inspection of the muffler and surrounding components. Checking for signs of rust, corrosion, or physical damage can provide insight into the potential causes of unusual sounds. Moreover, a professional mechanic can use diagnostic tools to assess exhaust pressure and identify hidden problems.

In summary, unusual muffler noises can signal various issues ranging from simple leaks to significant internal damage. Addressing these sounds promptly can prevent further complications and ensure optimal performance of the vehicle’s exhaust system.

Assessing the Impact of Resonator Damage on Engine Performance

The resonator plays a crucial role in the exhaust system, primarily by controlling sound and smoothing out the noise produced by the engine. When a resonator suffers damage, it can significantly affect both engine performance and the auditory experience of the vehicle.

One of the most immediate impacts of resonator damage is the alteration of exhaust flow dynamics. A compromised resonator can create back pressure, which restricts the efficient expulsion of exhaust gases. This restriction may lead to a decrease in engine power and acceleration, negatively influencing overall performance.

Furthermore, damaged resonators are often responsible for increased noise levels. The primary function of a resonator is to reduce unwanted sounds from the exhaust system, and when it fails, drivers may experience a louder, more aggressive noise profile. This elevated noise can be distracting and uncomfortable, making long drives less enjoyable.

In addition to affecting performance and noise levels, resonator damage can also change the engine’s fuel efficiency. When the exhaust flow is impeded, the engine may compensate by using more fuel to maintain power output, leading to increased consumption and higher operational costs.

Ultimately, assessing resonator health is essential for maintaining optimal engine functionality. Regular inspections and prompt repairs can prevent major issues, ensuring that both performance and noise levels remain within desired parameters.

Steps for Repairing or Replacing a Faulty Muffler

Identifying and addressing issues with your diesel muffler is essential for maintaining optimal vehicle performance. Follow these steps to repair or replace a faulty muffler effectively.

1. Diagnose the Problem: Start by assessing the extent of the noise coming from the muffler. Unusual sounds may indicate damage or blockages. Listen for hissing or rattling, which often signifies a serious issue that requires prompt attention.

2. Gather Necessary Tools: Before starting the repair process, ensure you have all required tools, including a jack, jack stands, wrenches, and a replacement muffler if necessary.

3. Raise the Vehicle: Safely lift the car using a jack and secure it with jack stands. This allows for easy access to the exhaust system and muffler.

4. Inspect the Muffler: Examine the muffler for visible damage such as rust, holes, or loose components. A thorough inspection can help determine if a repair is possible or if a replacement is needed.

5. Remove the Old Muffler: If replacement is necessary, disconnect the muffler from the exhaust pipe using wrenches. Carefully remove any hangers or brackets holding it in place.

6. Install the New Muffler: Position the new muffler in place, securing it to the exhaust system. Ensure that all connections are tight and that the muffler sits properly within its hangers.

7. Test for Leaks: Once installed, start the engine and listen for any unusual noise. Inspect the connection points for exhaust leaks, which might indicate improper installation.

8. Lower the Vehicle: After confirming there are no leaks and the noise is resolved, safely lower the vehicle back to the ground.

9. Dispose of the Old Muffler: Properly dispose of the old muffler according to local regulations, as it contains materials that may be harmful to the environment.

These steps will help you effectively address any issues with your diesel muffler, ensuring a quieter ride and improved vehicle performance.